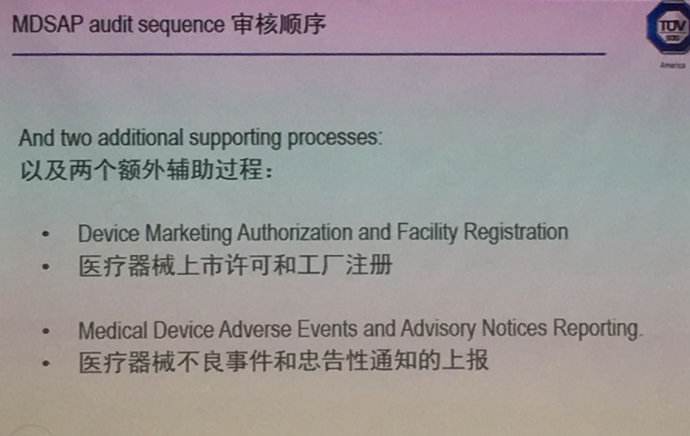

The MDSAP certification program aims to establish a single audit process that meets and unifies the audit requirements of the aforementioned countries, making the audit more comprehensive and effective. The regulatory agencies of the five countries above recognize the audit results of MDSAP, and production enterprises can reduce the number of audits corresponding to different regulatory agencies, thereby reducing production interference caused by audits. The introduction of MDSAP certification has standardized the audit process internationally and reduced the burden on production enterprises.

The Medical Device Single Audit Program (MDSAP) project is a new set of audit procedures recognized and joined by regulatory agencies in the United States (FDA), Australia (TGA), Brazil (ANVISA), Canada (HC), and Japan (MHLW). The program aims to establish a single audit process, meet and unify the audit requirements of the aforementioned countries, and make the audit more comprehensive and effective. Regulatory agencies in these five countries recognize the audit results of MDSAP, and production enterprises can reduce the number of audits corresponding to different regulatory agencies, reducing production interference caused by audits. The introduction of MDSAP standardizes the audit process internationally, reducing the burden on production enterprises. Through the continuous participation of production enterprises, the MDSAP certification project will gradually improve and is expected to be officially launched in 2017.

Chinese medical device exports to the United States require FDA review, approximately every two years. Chinese medical devices account for less than 10% of the import share of medical devices in the United States. However, the number of Chinese audits accounts for more than 13% of the FDA's global non US audits, indicating the increasing focus of the FDA on Chinese companies; The number of audits conducted by the FDA on Chinese factories is increasing at a rate of 50% annually, and the proportion of companies with the FDA's audit conclusion of "zero defects" is only 18% to 28%, far lower than the international average of 47%.

Renni MDSAP certification

Renni has 16 years of experience in the medical device industry, serving as a consultant for medical device regulations and systems

Renni is proficient in CFDA, FDA, and CE regulations for medical devices

Renni is proficient in ISO13485/YYT 0287, ISO14971/YYT 0316, QSR820, JGMP, GMP quality system, etc

Renni excels in providing guidance on medical devices for the US FDA QSR820 and is proficient in meeting the requirements of various challenging subsystems of QSR820

Renni has successful experience and cases in consulting and coaching dozens of medical device companies, helping them successfully pass the FDA QSR820 audit in the United States, and some companies have obtained zero defect approval; And assist enterprises in obtaining ISO13485 certificates, CE certificates, CMDCAS certificates, etc.

A professional team with extensive experience in US regulations can provide timely and efficient services. At present, we are one of the consulting institutions in China that has successfully provided guidance on FDA warning letter lifting and blacklist removal